Carbonization Furnace

Carbonization is a kind of way to make all kinds of biomass into charcoal. And carbonization furnace is kind of equipment to make this happen.

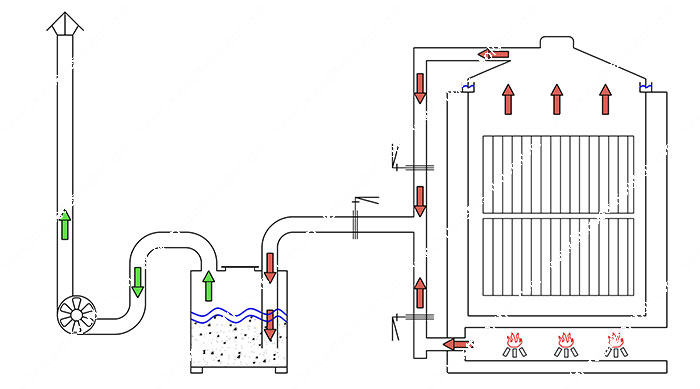

Working principle

Feature

1. High carbonization rate;

2. Energy-saving;

3. Smokeless;

4. Easy operation;

Step

Carbonize your product with following steps:

1. Put the material in the stove

wood sawdust briquette: Put it in the steel basket, then use the hoist to put the steel basket into the inner stove;

woo log, wood branch, bamboo etc: Put them neatly in the basket, then put the basket into the inner stove;

coconut shell, nuts shell etc: Beat into even part, then fix the small part in the basket and put the gasket into the inner stove.

2. Carbonization

Seal the stove then carbonization work begins.

Carbonize time

Wood briquette: about 6 hours;

Other material: depend on the moisture and the material size;

3. Take out gasket

Take the gasket by the hoist, put it somewhere to self-cool down. Then put another fixed gasket into the inner stove for another carbonization process.

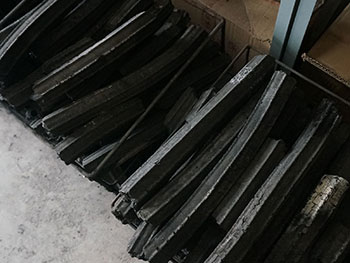

4. Get the charcoal

After the cool down process finished, you get the charcoal, take it out from the gasket!

Gasket &hoist

Things to pay attention to on making high-quality charcoal in carbonization process

- If your material is high in moisture, take 3-5 hours to evaporate the moisture of wood logs (small fire 90 -150 degree, white and heavy color water vapor smoke).

- A six hours step on carbonization is like the following: 150-280 degree (yellow and heavy smoke), 3 hours, 280-450 degree (thin and smaller smoke), 2 hours, 450-higher, 1 hour (lucid and blue color smoke).

- Long cooling time helps to make better quality charcoal.

Carbonizing rate

| Material | Moisture | Carbonizing rate | Heating value (Kcal) | Fixed carbon |

| wood briquette | ≤20% | 40-50% | 6700-7500 | 69-80% |

| wood log | ≥30% | 22-25% | 6000-6500 | 60-70% |

| wood | ≤20% | 33-35% | 6000-6500 | 60-70% |

| coconut shell | ≤10% | 30-35% | 7500-8000 | 76.8-85% |

| bamboo | ≥30% | 30-35% | 7000-8500 | 65-75% |

Material

Almost all the biomass can be made into charcoal, we list some as follow: Wood logs, wood branches, sawdust briquettes, biomass waste, coconut shell, Macadamia nut, cashew nut shell, bamboo, etc

wood briquette charcoal

wood briquette charcoal wood log charcoal

wood log charcoal coconut shell charcoal

coconut shell charcoal walnut shell charcoal

walnut shell charcoalParameter

| Model | Power(kW) | Input capacity(t/h) | Weight (T) | Volume(m³) | Temperature(ºC) | Accessories |

| CFR1 | 0.75 | 3/24 | 4 | 2.75 | 400-600 | 1*outer furnace, 3*Inner pots,3*covers, 1*purification tank, 1*3t lifting device |

| CFR2 | 0.75 | 6/24 | 8 | 2.75 | 400-600 | 2*outer furnaces, 6*Inner pots,6*covers, 2*purification tank, 1*5t hoist equipment with motor |

| CFR3 | 0.75+1.5 | 9/24 | 12 | 2.75 | 400-600 | 3*outer furnaces, 9*Inner pots,9*covers, 3*purification tank, 1*5t hoist equipment with motor |

| CFR4 | 0.75+1.5 | 12/24 | 16 | 2.75 | 400-600 | 4*outer furnaces, 12*Inner pots,12*covers, 4*purification tank, 1*5t hoist equipment with motor |

Energy consumption (kg/h): 20-30 (firewood) , 15 (liquid gas).

CFR3