Inclining Conveyor

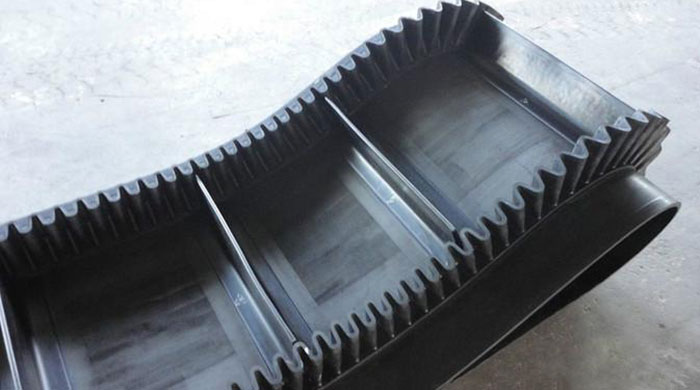

Inclining conveyor is also called corrugated sidewall belt conveyor. In some conditions, due to the limit space or in case of lifting materials at a large slope, inclining belt conveyor is always used to avoid material spilling. This system can convey materials vertically and also can work at a large slope from 0 degrees to 90 degrees, and allow heavy load material conveying. It is widely used in recent years due to the requirement of conveying height, conveying capacity.

Inclining conveyor consists of the side wall and cross cleats which are advanced and simple in structure, and is easy to maintain.

Application

Vertical shaft, coal mine, subway, self-unloading ship, continuous ship unloaded, cereal, metallurgy, chemical, cement.

Mining, metallurgical and coal industry to transfer sandy, lump materials, and packaged materials in large slant angle.

Feature

According to different transferring equipment, the transfer system can be one solely or multi-conveyors or combined with other transfer equipment.

Inclining conveyor can be installed horizontally or aslope to meet the needs of different transfer lines.

simple structure, steady performance, easy to fix,

Conveying at a big inclination, compact structure, small coverage area.

Parameter

| Belt width (mm) | Side wall height(mm) | Part angle throughput (m³/h) | Dimensions | ||||||

| 30° | 45° | 60° | 90° | Height of first roller(mm) | Height of tail roller (mm) | Height of belt surface (mm) | Width of anchor (mm) | ||

| 300 | 40 | 15 | 11 | 8 | 4 | 350-1000 | 335 | 450 | 480 |

| 60 | 14 | 10 | 7 | 4 | |||||

| 400 | 60 | 20 | 14 | 10 | 5 | 330-490 | 500-700 | 580 | |

| 80 | 34 | 26 | 18 | 10 | |||||

| 500 | 80 | 46 | 35 | 25 | 13 | 1100-2000 | 600 | 760-800 | 870 |

| 120 | 71 | 57 | 40 | 21 | |||||

| 650 | 120 | 104 | 83 | 58 | 31 | 1300-2000 | 600 | 800-850 | 1020 |

| 160 | 120 | 97 | 69 | 37 | |||||

| 800 | 120 | 128 | 102 | 72 | 38 | 600-800 | 800-1115 | 1220 | |

| 160 | 157 | 127 | 90 | 48 | |||||

| 200 | 195 | 157 | 112 | 60 | |||||

| 240 | 235 | 195 | 142 | 76 | |||||

| 1000 | 120 | 172 | 137 | 96 | 51 | 1400-2000 | 600-800 | 800-1200 | 1440 |

| 160 | 216 | 175 | 124 | 66 | |||||

| 200 | 267 | 216 | 157 | 83 | |||||

| 240 | 327 | 271 | 197 | 106 | |||||

| 1200 | 160 | 275 | 222 | 158 | 85 | 800-1000 | 1050-1500 | 1690 | |

| 200 | 331 | 267 | 192 | 102 | |||||

| 240 | 419 | 347 | 253 | 136 | 1600-2000 | ||||

| 300 | 466 | 384 | 178 | 149 | |||||

| 1400 | 160 | 319 | 258 | 184 | 98 | 800-1200 | 1050-1700 | 1890 | |

| 200 | 395 | 318 | 226 | 121 | |||||

| 240 | 500 | 414 | 302 | 162 | |||||

| 300 | 564 | 465 | 337 | 180 | |||||

| 400 | 794 | 680 | 524 | 281 | |||||