Mill scale briquette machine, briquetting plant and making process

Use mill scale briquette machine can turn the small mill scale into briquette and is suitable to use in the furnace like EAF, converter, BOF, etc.

What is mill scale

Mill scale is a kind of by-product from the steel making and rolling process, its main components are FeO, Fe2O3, Fe3O4 and a small amount of iron and other impurity elements, with the content of TFe around 70%.

The richness of its iron content makes it a very attractive industrial waste. It represents about 2% of steel produced. As the massive capacity of the steelmaking worldwide today, 13.5 million tons of mill scales are generated annually.

The usage of mill scale

Mill scale has wide usage in the steel plant, 90% of mill scale is directly recycled within steelmaking industry and a small amount is used in other industry like cement plants, petrochemicals industry, etc.

The main usage

- Used for sintering (auxiliary material).

- Used in steelmaking (use directly or use as briquette).

- Used to make sponge iron (DRI).

- Used to make ferrosilicon alloy (an alternative for steel scrap).

- Used to produce the iron oxide red, iron oxide yellow, iron oxide black.

- Etc.

Mill scale used in steel making process

Most of the mill scale is used in steelmaking by way of sintering, direct use or briquetting.

Sintering

Sintering can help to increase the grade of the sintering mineral, reduce energy cost. The existing sintering machine can be directly used to deal with the mill scale, it’s easy to operate, less investment and rapid, good economic returns.

But it is with poor operating conditions, difficult for storage and transportation, and also low utilization. To prevent the fan blades to cover oil and air pollution, the oil content of the mill scale should be lower than 1%.

Direct use

Mill scale has the functions of slagging, temperature control, reducing the material cost when used in the furnace. And it can be directly used. Dried mill scale will be fed in the top furnace silo then use in the furnace.

Compare to be used for sintering, it’s more direct and more economical.

But when it’s fed in the silo, as the mill scales are not big enough, part of them will be sucked away by the dust collecting system. This reduces the utilization rate of the mill scale itself.

Briquette

Briquette is another way of making use of the mill scale in the furnace. It solves the sucking problem by turning the mill scale into useful briquettes.

When the slag refluxes, adding mill scale briquette will rapidly increase the rate of the iron oxide, make the slag smelts quickly, effectively reduce the consumption of steel in the smelting process.

Why make mill scale briquette

Mill scale briquette is an alternative way of direct use. Besides the advantage of reducing the mill scale loss in the dust collector, it also has other benefits.

- Briquette makes the mill scale easy to transport and store, also a lower loss on these processes.

- The dust collector will have a higher efficiency due to the lower dust from the raw material.

- The briquette can make use of other materials like steel slag, mineral powder, fly ash, etc. By mixing them with mill scale and briquetting.

- The briquette is easy to dry in 2-3 days’ air drying. It helps to reduce the energy cost on the drying process.

The mill scale briquetting process

To set up a mill scale briquette plant, the core machine is the mill scale briquette machine, beside this, other machines are also required like the screen machine, mixing machine, conveyer, etc.

The process usually following the way below

Mill scale ⇒ Screen ⇒ Mixing ⇒ Briquette ⇒ Storage for drying

The screen machine is needed as the large particle impurity and iron block which are not suitable for briquetting should be picked out as a protection for the briquette machine.

Mixing process will mix the mill scale along with other materials and binder to make them evenly distributed and better performance on briquette process.

Mill scale briquette machine for sale

Roller briquette press machine is used for briquetting mill scale.

Two types of roller press can be chosen as the mill scale briquetting machine.

Mill scale is a material for briquetting with a pressure not that big, a normal type roller briquette press machine can even afford the work. As it’s good performance and a much lower price, it is much popular than the hydraulic type nowadays. It also can equip roller with the same material as the hydraulic type.

Hydraulic type roller briquette press can supply a pressure much bigger than the normal type. By using the hydraulic system, it also increases the service life of the roller and motor by preventing it from blocking. Pressure is easy to adjust with the hydraulic system to meet your demand.

normal type

normal type hydraulic type

hydraulic typeMaxton – the mill scale briquette making machine manufacturer

Maxton supplies the roller mill scale briquette machines for decades. We have strong technology and experience on the mill scale briquette making system. The well designed line will help you to reduce your investment and higher the system efficiency.

Better spare part is chosen to make a long service life for your mill scale briquette line.

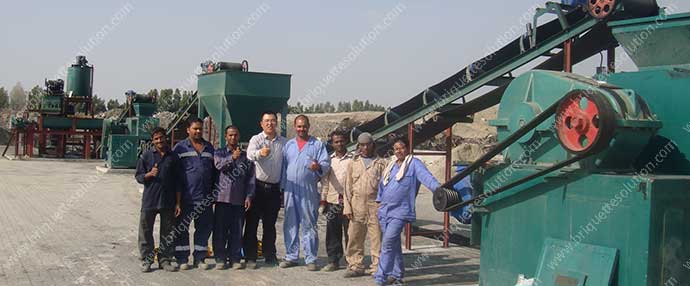

20 tons per hour mill scale briquette plant show

Herewith is a video for the mill scale briquetting plant set by Maxton in the Middle East for your reference.