Biomass residual and biofuel – recycle bio waste by briquetting

The development of clean energy and global climate change is the center stage of the current international community. As a renewable clean energy, biomass briquette (biofuel) is the only energy that can be stored and transported and has the lowest heating cost among the solid renewable energy sources. Biomass briquette (biofuel) is comparable to coal middings (medium quality coal) of the same density, and is a high-quality alternative fuel for coal. Many properties are even better than coal.

What is biomass briquette

Biomass briquette making is a typical recycling way for biomass waste. By using this way, we turn the loose and waste material into a useful fuel.

The briquette is made by briquetting the raw biomass which has been dried, crushed, etc. We get the briquette with a certain shape and a certain density.

The shape, size and density can be varied from different briquetting technology and machines.

Why turn biomass to briquette

The calorific value generated by the full combustion of biomass briquette fuel is equivalent to that of coal middings (medium quality coal) of the same density, and the emissions generated during the combustion process will not pollute the environment, can be used as an alternative fuel for fossil fuels.

| Type | Calorific value (Kj/Kg) | Density (g/cm3) | Ash % | Sulfur % |

|---|---|---|---|---|

| Soybean straw briquette | 16744-17163 | 1.1-1.3 | 3-4 | 0.2 |

| Wheat straw briquette | 15917-16744 | 1.1-1.3 | 15-19 | 0.11-0.36 |

| Wood | 16744 | 0.47-0.64 | 1-3 | – |

| Coal midding | 16744-18837 | 0.8-1 | 30-40 | 1-2 |

Besides, cause briquette improves the original raw material properties, these biofuel briquettes are easier to store and transport.

Compared with direct combustion, the fuel itself is denser and free of debris, with longer combustion and utilization time, lasting and stable. It is not easy to cause insufficient combustion or much impurities generated problem during the combustion process.

After burning out, the pollutants contained in it are very small and will not affect the environment. It is such good clean energy.

The mechanism of biowaste briquetting

There are several binding modes between the molecules of biomass briquetting particles:

1. The molecules are bonded together due to mutual attraction;

2. The molecules cross and fuse with each other to form a “solid bridge” structure, and the “solid bridge” binds the molecules together;

3. Fold interlocking is formed between biomass fibers.

During the biomass briquetting process, two main factors should be considered: the ability of the biomass powdery feedstock to form a biomass briquette and the ability of the briquetting process to increase the density of the biomass briquette.

The lignin content has a great influence on the internal bonding of the particles. The higher the lignin content, the stronger the intermolecular force of the particles, the better the internal bonding, the better the physical properties of the formed particles when the temperature is higher than the glass transition temperature.

After the crushed biomass is subjected to a certain temperature and pressure, the plasticity of the lignin, protein and other components in the material will fill the gaps between the particles, and the particles will be connected to each other to form a relatively stable whole briquette.

Find the pdf file of biomass briquetting technology to help you know more about this.

Sources of biomass residual

Wood Residue

Includes wood those materials derived from a manufacturing process, those derived from a logging process, and those that are reused or recycled. Mainly including all kinds of sawdust, fuel wood, charcoal, waste wood and forest residues.

Agricultural residues

Most of the agricultural residues are straw, hub, etc. They are produced in agricultural production processes, and the use of these residues to obtain heat energy is the most common way. Briquetting is a way to greatly improve the efficiency of this heat energy acquisition.

Dedicated Energy Crops

Dedicated energy crop/dedicated biomass crop is specially used for large-scale artificial cultivation of plants that produce, process and form energy-based bio-based products other than food and feed. Mainly refers to the perennial fiber and oil plants, in addition to the production of chemical materials and natural fibers, mainly for the production of commercial bioenergy. Compare to energy plant, dedicated energy crops are all domesticated.

Examples: switch grass, miscanthus, willow, eucalyptus, jatropha, etc.

Municipal Solid Waste (MSW)

MSW is a complex mixture of many different solid wastes, according to the study of EPA, the amount of MSW keeps on increasing year by year, the total generation of municipal solid waste (MSW) in 2018 was 292.4 million tons ( in the USA). In order to make better use of MSW, classify it and utilize the resources available in it, extracted MSW can be recycled and reused by briquetting which we call it RDF.

Uses of biomass waste briquette

Biomass energy can be used not only as fuel by briquetting, but also as raw material for biomass processing like power generation, activated carbon processing, and biomass liquefaction fuel.

In Europe and the United States, the commercial operation of manufacturing and selling biomass fuels for household and industrial use and supporting clean small-scale combustion boilers is very mature.

Taking the United States, Sweden and Austria as examples where biomass energy is with high utilization. Biomass energy accounts for 4%, 16% and 10% of one-time energy consumption respectively, and about 15% of electricity comes from biomass power generation. This proportion is expected to increase to 17% by 2023. It is estimated that the global biomass energy market will reach 15.47 billion US dollars in 2025, mainly used for power generation, heating and other fields.

Until the end of 2019, there were more than 450 biomass power plants, and the installed capacity is still increasing. For example, the total biomass power generation in the United States is nearly 7,358 MW.

Europe, with biomass energy accounting for nearly 60% of renewable energy, and about 75% bioenergy used for heating and cooling. Sweden is a typical country that utilizes biomass energy. Its annual biomass fuel output exceeds 2 million tons, and its per capita consumption exceeds 160 kg. UK plans to grow biomass by 60% to account for 9.5% of energy demand by 2026.

Biomass briquette VS coal

The CO2 produced by the combustion of biomass solid briquette fuel is absorbed by the plants during the growth period and will not increase the total CO2 content in the atmosphere. It is called CO2 zero-emission, also known as carbon neutrality.

When the biomass briquette fuel is burned, the emission of NOX (nitrogen oxide) is 1/5 of that of coal, SO2 is 1/10 of that of coal, soot is lower than 127 mg/m3. Combustion speed is 11% faster than coal, full combustion, less black smoke, low ash content, and the emission concentration of air pollutants is far lower than the national standard. The performance of those briquettes is greatly improved, combustion efficiency increases to 30%-40% which direct combustion of is only 10-15%. Also has good ignition and fire banking performance.

Suitable for long-term storage and long-distance transportation. the calorific value of the briquette fuel is about 14-17 MJ/kg, while the calorific value of ordinary coal is about 21.7 MJ/kg. If we only consider the calorific value, 1 ton of briquette fuel is equivalent to 0.67 t of coal, but the combustion efficiency of briquette fuel is greatly improved, thus its equivalent value with coal should be greater than 0.67.

Benefit of biofuel briquette

- Biomass briquette fuel has big calorific value about 3500-4500 kcal. It is small in size, saves storage space, convenient for transportation, and reduces transportation costs.

- Biomass briquette fuel has high purity, high combustion efficiency, easy to burn out, and less residual carbon. It does not contain other impurities that do not generate heat, and absolutely does not contain coal gangue, stones and other impurities that do not generate heat but consume heat, which will directly reduce costs for enterprises.

- Biomass briquette fuel does not contain sulfur and phosphorus, and doesn’t corrode the boiler, which can prolong the service life of the boiler. It does not produce sulfur dioxide and phosphorus pentoxide during combustion, so it will not cause acid rain, pollute the atmosphere, and pollute the environment.

- There is very little ash ballast after the biomass briquette fuel is burned, which greatly reduces the site for the promotion and application, and reduces the cost of the slag removal.

- Biomass briquette fuel is clean and hygienic, easy to feed, and the ashes after burning are high-quality organic potash fertilizers with extremely high grades, which can be recycled to generate profits.

Biomass briquetting process

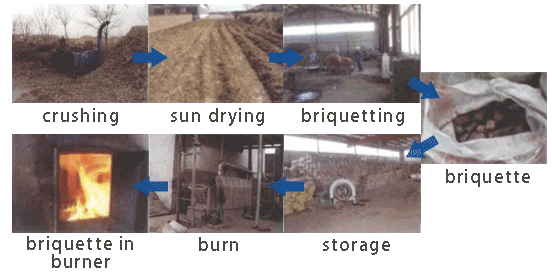

The process of biomass briquetting mainly includes raw material collection, crushing and briquetting.

The first step is simply packaging, cutting, baling and transporting the biowaste. Then crush, screen, dry or mix in the material yard. Finally, it is transported to the briquette machine and is made into various shapes and sizes through different briquette machines.

The Chinese “Biomass briquette fuel quality classification” (NB/T34024-2015) stipulates the quality that the density of biomass briquette fuel should be 800~1 300 kg/m3, the moisture less than 15%, ash content is 0.7%~15%, base calorific value is 12~18 MJ/kg.

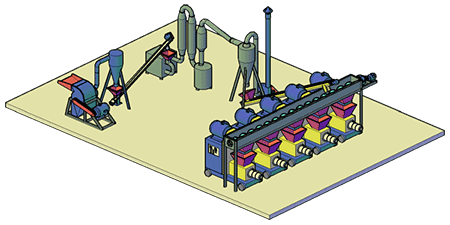

Plant layout

A biomass briquette system would include several machines to make it run. Crusher, dryer, briquette machine and handling machines.

Process description

Crushing

Crushing is the basic treatment of materials before briquetting. The quality of crushing directly affects the performance and product quality output from the briquetting machine. When the raw material particles are too large and directly briquettting, the crushing behavior in the briquetting process will cause the briquette machine to consume more energy. And the crushing efficiency of the briquette machine is much smaller than that of the crusher.

For small material like sawdust and rice husk, etc, we only need to clean out the hard objects such as stones, no crushing is needed.

Drying

Moisture is critical for briquetting. In the briquetting process, when the moisture content is too high, the volume of the raw material expands with the increase of temperature, which may lead to an explosion accident. When the moisture is insufficient, the bonding force between the particles decreases, which affects the briquetting performance.

Dryers can be used to dry the material in a short time, commonly used drying equipment are air flow dryer, rotary dryer, etc. Natural drying is also a way aviliable.

Briquetting

There are 2 ways to briquette those materials, natural briquetting and heating briquetting. Both of them are binder free way which uses the internal soften/melt lignin to combine the particles.

Natural briquetting shall have a temperature of about 100 Celsius, heating briquetting takes place at a temperature of around 150-300 Celsius. High temperature improves the briquetting performance in 3 ways.

- It softens/melts the lignin and makes the bond better.

- It softens the raw material and makes it easier to be briquetted.

- It increases the efficiency of the briquette machine.

typical practical agricultural residue briquette process

typical practical agricultural residue briquette processBriquette machines

Screw briquette machine

The machine uses the screw to extrude the biomass, external heating is used to maintain a certain briquetting temperature to soften the lignin, cellulose, etc., then extrude biomass briquettes. The moisture of the raw material should be controlled between 6-12% to avoid cracking or gas explosion when output the product.

This equipment runs smoothly and has good production continuity. The biggest problem is the wear of the screw. In order to solve this problem, the head of the screw has been subjected to wear-resistant surfacing treatment.

Log briquette maker

This type of machine uses the reciprocating motion of the piston to compress the biomass. Using the energy stored in the flywheel, through the crank connecting rod structure, the punching piston is driven to punch the loose biomass into dense briquettes. These briquettes are usually solid. The density of the obtained product is usually between 0.8-1.1g/cm3. The required moisture is much looser than that of screw type, and highly improves the wear problem of the mold.

Comparation table for the two common biomass briquette machines

| Type | Screw briquette machine | Log briquette maker |

|---|---|---|

| Heating | Yes | No |

| Raw material size (mm) | ≤3-5 | ≤20-30 |

| Raw material moisture | 6-12% | 5-20% |

| Briquette density (g/cm3) | 1.1-1.4 | 0.9-1.3 |

| Consumption (kW*h/t) | 100 | 40-60 |

| Maintain frequency | high | low |

| Price | low | medium |

Due to its particularity, biomass briquetting does not need binders in many cases. When binder is needed, generally, choosing binders mainly should consider the cost, effect and environmental friendliness. Some near-zero-cost industrial wastes can also used as binders in the biomass briquetting process, like cellulose by-products from the paper industry, food sludge, and sugars extracted from fruit wastes. These substances are inexpensive and readily available and can significantly reduce the cost.

Other recycling ways for biomass waste

Biogas

Developed countries mainly develop anaerobic technology to treat livestock manure, high-concentration organic wastewater and garbage for power generation and fertilizer recycling. In developing countries, biogas digester technology is mainly developed, and biogas is produced by using crop straw and livestock manure as raw materials as living cooking fuel.

Biomass gasification

Biomass gasification is currently mainly used for heating, kilns, power generation and synthetic fuels. As early as the 1970s, some countries started the research and development of biomass thermal cracking gasification technology. At present, biomass gasification power generation and centralized gas supply have been partially commercialized in Europe and the United States, forming large-scale industrial operations. Sweden, Denmark, Austria, Germany, USA and Canada, etc. are the leading countries of this technology.

Biomass fuel ethanol

Brazil is the most distinctive country in the development and application of ethanol fuel. In the mid-1970s, in order to get rid of excessive dependence on imported oil, the world’s largest ethanol development plan was implemented. By 1991, ethanol production reached 13 billion liters, and 9.8 million vehicles Nearly 4 million vehicles are pure ethanol vehicles, and most of the rest use a 20% ethanol-gasoline blend. By 2013, the United States accounted for 56.77% of fuel ethanol production over the world, Brazil 26.75%, the EU 5.85%, China 2.97%, and India 2.33%.

Biodiesel

Refers to fatty acid methyl esters or fatty acid ethyl esters made from animal and vegetable oils and fats through esterification or transesterification processes. Europe is the world’s largest and most developed biodiesel market. In 2003, 90% of the world’s biodiesel was sold in Europe, accounting for 5% of the refined oil market. The success of biodiesel in Europe is mainly due to policy support. In 2010, biofuels replaced 5.7% of diesel consumption, and the expected demand for biodiesel in the EU market will rise from 3 million tons to nearly 10 million tons. Europe currently allows the blending of 5% biodiesel that meets the EN14214 standard in petrochemical diesel, and 100% biodiesel can already be used in today’s trucks and buses without changing any components.

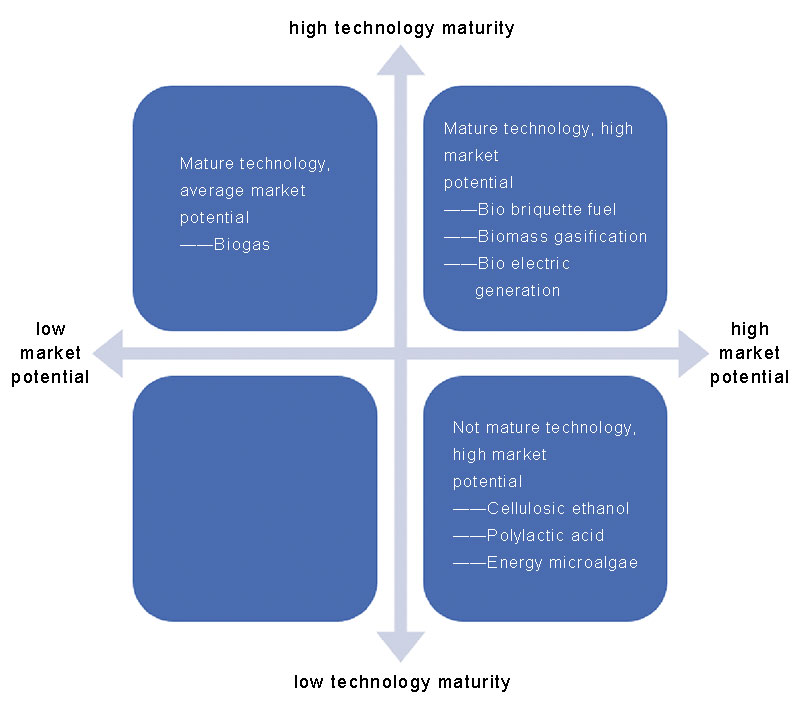

Biomass waste recycling market

At present, the research on the market development and utilization of biomass waste energy mainly focuses on three directions: first, biomass briquette as fuel, the combustion generates heat. Second, biochemical transformation, that is, through fermentation and anaerobic digestion substance conversion obtains liquid or gas fuel. Third, through the thermochemical conversion of biomass, to produce three high-quality energy products in solid, liquid and gas.

Among them, biomass briquette fuel has low cost, simple process and good economic benefits. The calorific value and benefit of biomass briquette fuel are obviously better than that of ordinary coal, and the greenhouse gas emission of the fuel is less than one-ninth of that of coal. It is an important direction of biomass energy conversion and utilization in the current market.