Sludge Briquette Machine Guideline

Sludge briquette machine recycles the sludge by briquetting them for blast furnaces.

Damage of the sludge

The steel making process makes a lot of sludge (about 8 to 12% of the steel production), such the blast furnace sludge, gas sludge, steel rolling sludge, steel rolling iron oxide scale, sintering dust, steel pipe graphite sludge, etc. Get rid of these sludge will help the plant to reduce the cost for the product and prevent pollution.

- Pollution for the field

The sludge needs a lot of filed to be placed and will sink into the soil with the rain, change the content of the soil and even with heavy metal.

- Pollution for the atmosphere

The placed sludge produces an exothermic reaction which makes harmful gas. It also causes dust pollution with the wind.

- Pollution for the water

The content of CaO and MgO in these sludge will turn into corrosive strong alkaline hydroxide which will be away with water, these materials also turn the nearby water and soil with high PH value.

The ingredient of the sludge

The main ingredient of the sludge is usually iron oxide and calcium oxide, It also contains oxides such as silica, magnesia, and alumina, which further may contain zinc oxide and lead oxide, depending on the type of scrap used. These ingredients will fluctuate with changes in the number of raw materials, molten iron, and flux added during smelting. At the same time, they will change with the oxygen supply system, furnace operation conditions, dust removal, and sewage treatment systems.

The main composition of sludge in steel plant (%) – reference only

| TFe | SiO2 | C | CaO | |

|---|---|---|---|---|

| steel rolling sludge | 69.55 | 1.6 | 19.6 | 0.6 |

| gas sludge | 23.89 | 4.32 | 47.3 | 2.8 |

| blast furnace sludge | 56.03 | 22.8 | 4.1 | |

| electric furnace sludge | 22.34 | 7.0 | 3.02 | 24.0 |

Make value from the sludge

The iron dust sludge usually contains CaO and FeO, the sludge briquette can be used as the slagging agent, flux in the steel making process. These sludge, which is full of tiny particles, also helps to make the briquette quality better when mixed with other materials.

The benefit of using blast furnace sludge briquette.

- Advanced the slag removal time, reduce the smelting time.

- Replace fluorite briquette, make protection for the environment and improve the service life of the furnace.

- Reduce the CaO briquette cost.

- Early dephosphorization and poly phosphorus dephosphorization due to the fast slag and more content of FeO and CaO.

- Reduce iron and steel consumption.

- Shorten the oxygen supply time, reduce oxygen consumption.

Directly briquette them is a good choice for recycling. The process is easy and with low investment.

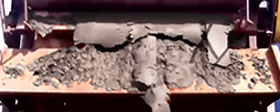

Use roller briquette press machine to make sludge briquette

Roller briquette press machine has a wide range of uses including sludge briquette making. The two types of roller briquette press (normal type and hydraulic type) are both suitable for sludge briquette making. By using these briquette machines, different moisture is required for the two types.

Roller briquette press machine is widely used in steel plant beside sludge briquette making, the roller briquette press also involved in the steel mill by-products of

Mill scales

Steel-grids

Coal + Coke fines

DRI fines

Ferroalloy fines

Iron pellet fines

EAF dust

Etc.

Binders

Binders help to improve the forming difficulty in sludge briquette making and make the briquette with higher strength. The commonest binder in sludge briquette making is cement and SiO2&CaO. Different binders are different in cost and availability, besides, in sludge briquette making, the rate of the binder, the moisture of the sludge, and briquette ball conservation time are also different.

Sludge briquette plant with roller briquette machine

Set up a sludge briquette plant, the most important thing we need to pay attention is the moisture. Normally, the original sludge has to be pre-treated to drive off the excess moisture to meet the requirement of briquette making.

The whole process

Raw sludge → Dry(if needed) → Crush → Mix → Briquette → Conservation

Find the roller briquette press machine for sludge briquette making