The briquette machine price and cost for setting up the briquette plant

Everyone who wants to buy a briquette machine always asks this very important question – what is the price of the machine? Today, let us analyze the cost of the briquette presses and what we should pay attention to about the briquette machine price.

Types of briquette machine and the briquette machine price

The most important thing of a briquette machine we must pay attention to is the type of the briquette making machines, we should find whether the type is suitable for our raw material or not, is it has a pressure big enough to make briquette with our ideal strength, is the briquette shape what we need.

So, how many types of briquette machines are there?

In Maxton’s briquette press dictionary, there are several types as below:

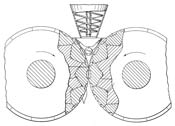

1. Roller type

Such as roller briquette press machine

The roller type machine has been widely used in industry, especially in the steel plant, it has features of large capacity and continuous work, as the pressure keeping time is much less than other type briquette machines, binders are always needed to help to make the briquette.

Price: medium low

Maintain cost: high

Maintain frequency: low

Maintain time: long

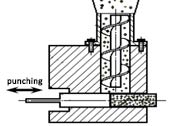

2. Punching type

Such as log briquette maker, coal charcoal briquette making machine

The punching type briquette machine uses the punch to make briquette, it supplies big pressure through the punch process. Most of the machines run in mechanical ways.

Price: medium

Maintain cost: medium

Maintain frequency: medium

Maintain time: medium

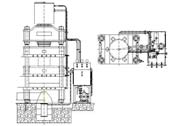

3. Hydraulic type

Such as hydraulic briquetting machine, hydraulic roller briquette machine

Hydraulic type briquette machine works with the hydraulic system which supplies a big adjustable pressure. In order to be suitable with the briquette pressure, the machines are equipped with spare parts with high quality.

Price: high

Maintain cost: low

Maintain frequency: medium

Maintain time: short

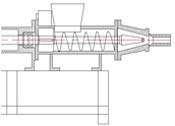

4. Screw type

Such as screw bio briquettes machine, extrusion briquette maker

Most of the screw type briquette machines are used for biomass with small capacity. As the biomass has an original binder – lignin, people always try to find ways to briquette biomass with a binder free way. Screw pressure is not big enough to make it flow. Thus other ways like heating are considered to solve the problem.

Price: low

Maintain cost: low

Maintain frequency: high

Maintain time: short

Applications of briquettes machine

Briquette machine has a wide usage from agriculture to industry. Make briquette is a way for recycling the waste and get value from them.

In agriculture

Agriculture has a lot of waste every year. These waste include agricultural and forestry by-products and processing residues, energy crops, and organic waste such as human and animal waste, etc. Biomass energy is the only renewable energy source that can be preserved. After making the biomass briquette, the volume is reduced by 20 to 30 times, the density can be around 1 t/m3, with low moisture, and easy to store or transport. Biomass energy accounts for about 15% of global energy, and in some countries, the proportion is even as high as 60-80%.

Common agriculture briquette machines

In industry

Recycling waste is always the topic in the industry. These “waste”, in industry, they even can make more value compare to the original raw material. Most of the waste for briquetting is the swarf and mining powder. By using these waste, we make a higher efficiency for the production line and protect the environment by reducing the raw material cost.

Common industry briquette machines

The price list for briquette making

There are a lot of things need to be considered before you buy a briquette machine or set up a briquette plant, the cost on the machine is an investment for only once but further consideration should be included as we should make value from the briquette.

A list of things need to be considered

Labor cost

Binder cost

Workshop cost

Trasport cost

Electric cost

Machine cost

Spare part cost (not only the cost on the spare part but also the replace time)

A general calculation should be done before you make your choice of purchasing the briquette plant, follow the instruction and regularly maintain your machine with care will help your briquetter run longer time and face lower default.